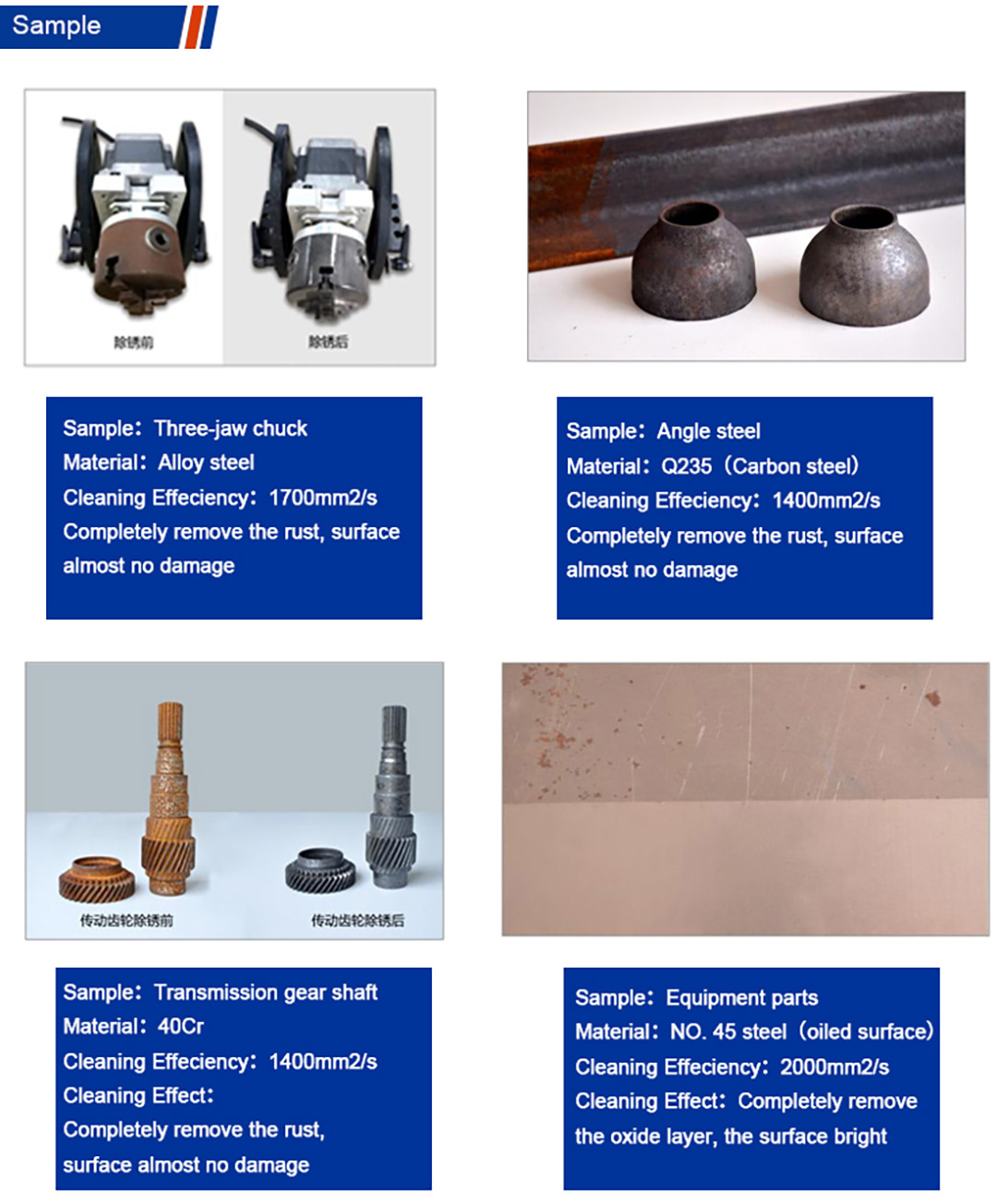

Sample: Three-jaw chuck Material: Alloy Steel Cleaning Efficiency: 1700 mm2/s Completely remove the rust, surface almost no damage

Sample: Three-jaw chuck Material: Alloy Steel Cleaning Efficiency: 1700 mm2/s Completely remove the rust, surface almost no damage

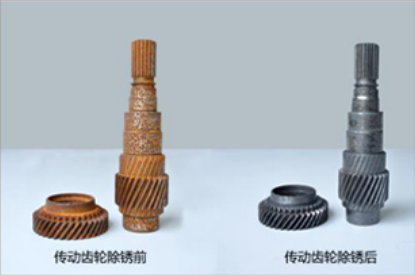

Sample: Transmission gear shaft Material: 40Cr Cleaning Efficiency: 1400 mm2/s Completely remove the rust, surface almost no damage

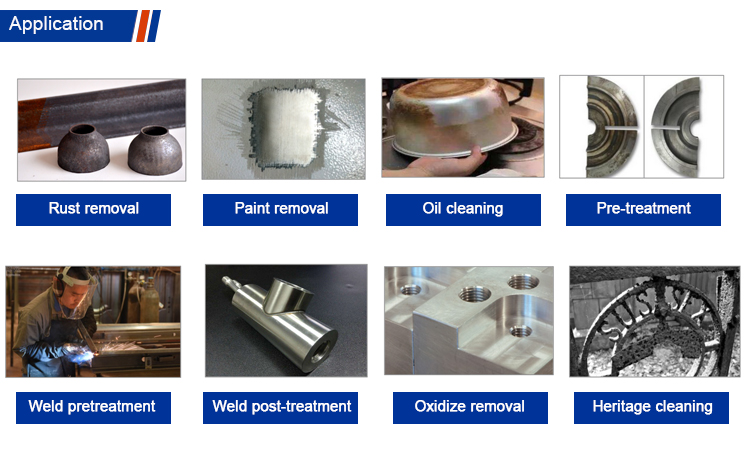

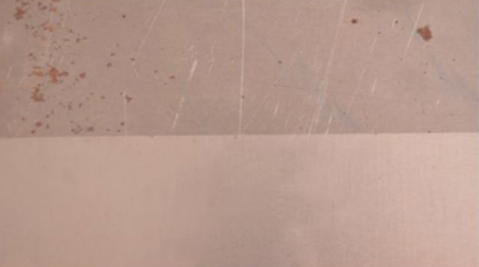

Sample: Transmission gear shaft Material: 40Cr Cleaning Efficiency: 1400 mm2/s Completely remove the rust, surface almost no damage 1. Automobile manufacturing. 2. Mechanical /electronic processing. 3. Cultural relics repair. 4. Mold /mould laser clean.Sample: Angle Steel Material: Q235(Carbon Steel) Cleaning Efficiency: 1400 mm2/s Completely remove the rust, surface almost no damageSample: Equipment parts Material: NO. 45 Steel (oiled surface) Cleaning Efficiency: 2000 mm2/s Cleaning Effect: Completely remove the oxide layer, the surface bright1. No damage to base material. 2. No consumption part. 3. Energy conservation and environment friendly. 4. High-efficient laser removal of oil, rust and paint.The new generation of backpack type laser cleaning machine combines light volume, easy operation, high efficiency cleaning, non-contact, non-polluting and equal to one, for cast iron, carbon steel plate rust cleaning, stainless steel, mold gear oil cleaning, aluminum plate, stainless steel baking paint oxide, cleaning effect of the surface is bright and clean, do not hurt the parent material. Advantages of MLA-CL-02. 1. Convenient design: compact structure, wearable, ergonomic, can be single person operation 2. High efficiency cleaning: high efficiency of laser cleaning, saving time 3. Non-contact: laser cleaning without abrasion and non-contact 4. No pollution: no need to use any chemicals and cleaning solutions, easily solve the problem of environmental pollution caused by chemical cleaning 5. Expandable: interchangeable Lens, change the depth of focus, laser cleaning a broader area MavenLaser is a manufacturer of precision laser welding equipment in China, we only focus on laser field research and development, dedicated to provide customers with comprehensive and complete laser welding full set of application solutions, research and development of laser equipment in China has been 14 years of history, to provide customers with continuous value creation. After years of efforts, MavenLaser has been a leader in the field of laser welding equipment development and application, and can provide ODM services for customers. At present, MavenLaser's main products include: handheld laser welding machine, automatic laser welding machine, high power laser welding machine, medical device laser welding machine, robot laser welding machine, jewelry laser welding machine, laser marking machine, laser deep engraving cutting machine, laser cleaning machine and laser rust removal equipment, etc. Cooperate with MavenLaser, we deserve your trust!

1. Automobile manufacturing. 2. Mechanical /electronic processing. 3. Cultural relics repair. 4. Mold /mould laser clean.Sample: Angle Steel Material: Q235(Carbon Steel) Cleaning Efficiency: 1400 mm2/s Completely remove the rust, surface almost no damageSample: Equipment parts Material: NO. 45 Steel (oiled surface) Cleaning Efficiency: 2000 mm2/s Cleaning Effect: Completely remove the oxide layer, the surface bright1. No damage to base material. 2. No consumption part. 3. Energy conservation and environment friendly. 4. High-efficient laser removal of oil, rust and paint.The new generation of backpack type laser cleaning machine combines light volume, easy operation, high efficiency cleaning, non-contact, non-polluting and equal to one, for cast iron, carbon steel plate rust cleaning, stainless steel, mold gear oil cleaning, aluminum plate, stainless steel baking paint oxide, cleaning effect of the surface is bright and clean, do not hurt the parent material. Advantages of MLA-CL-02. 1. Convenient design: compact structure, wearable, ergonomic, can be single person operation 2. High efficiency cleaning: high efficiency of laser cleaning, saving time 3. Non-contact: laser cleaning without abrasion and non-contact 4. No pollution: no need to use any chemicals and cleaning solutions, easily solve the problem of environmental pollution caused by chemical cleaning 5. Expandable: interchangeable Lens, change the depth of focus, laser cleaning a broader area MavenLaser is a manufacturer of precision laser welding equipment in China, we only focus on laser field research and development, dedicated to provide customers with comprehensive and complete laser welding full set of application solutions, research and development of laser equipment in China has been 14 years of history, to provide customers with continuous value creation. After years of efforts, MavenLaser has been a leader in the field of laser welding equipment development and application, and can provide ODM services for customers. At present, MavenLaser's main products include: handheld laser welding machine, automatic laser welding machine, high power laser welding machine, medical device laser welding machine, robot laser welding machine, jewelry laser welding machine, laser marking machine, laser deep engraving cutting machine, laser cleaning machine and laser rust removal equipment, etc. Cooperate with MavenLaser, we deserve your trust!

| Applicable Material | Stainless steel, Carbon steel, Aluminum, Wood, Stone, Metal |

| Wavelength | 1064nm |

| Max speed range | 1500-3000 mm/s |

| Advantage | clean surface ,no damage basement |

| Turn on/off time | 20Us |

| Power | 200W, 100W, 500W, 50W, 80W |

| Warranty of core components | 1 Year |

| Laser Type | Fiber Laser |

| Brand Name | Maven |

| Key Selling Points | protect the basement |

| Fiber length | 3-10M |

| Focal length | 20-50mm |

| cleaning energy | 1.5mj-8mj |

| Certification | CE |

| Dimension(L*W*H) | 562 X 368 X 300 |

| Item | Surface | Focal length(mm) | Efficiency(mm²/s) | Base Material Damage |

| Cast Iron | Severe corrosion (0.08mm) | >35mm | 3500 | No |

| Carbon steel | Mild corrosion (0.05mm) | >40mm | 3000 | >35mm |

| Stainless steel | Oil, slight corrosion | >50mm | 3200 | >35mm |

| Mould steel gear | Mild oily with scrap iron | >45mm | 4200 | >35mm |

| Aluminum | Oxide / surface spotting | >35mm | 3600 | >35mm |

| Stoving varnish | White stoving varnish(0.1mm) | >20mm | 3500 | >35mm |