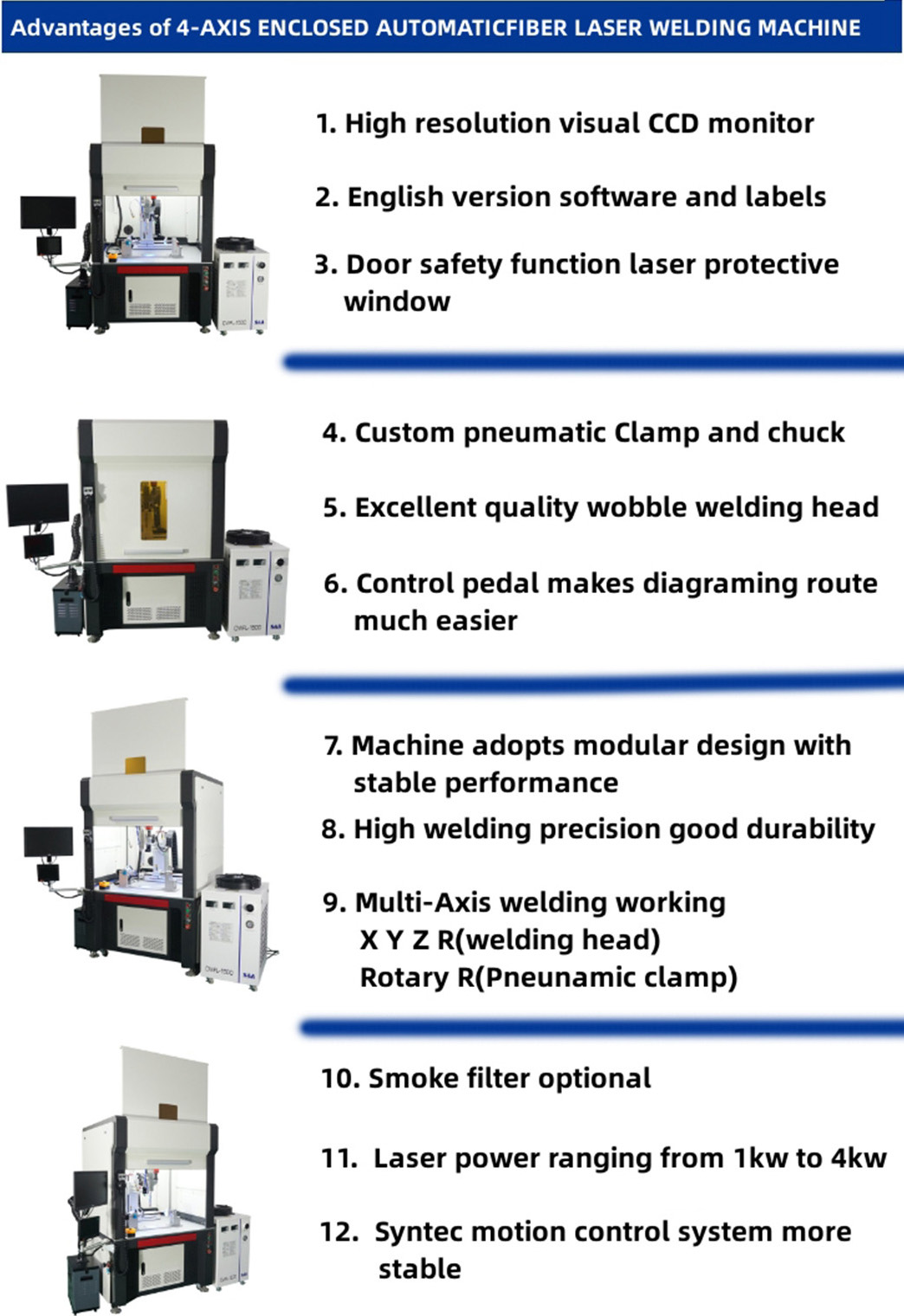

- Custom pneumatic Clamp and chuck

- Excellent quality wobble welding head

- Control pedal makes diagramming route much easier

- Machine adopts modular design with stable performance

- High welding precision good durability

- Multi-Axis welding working X Y Z R(welding head) Rotary R(Pneunamic clamp)

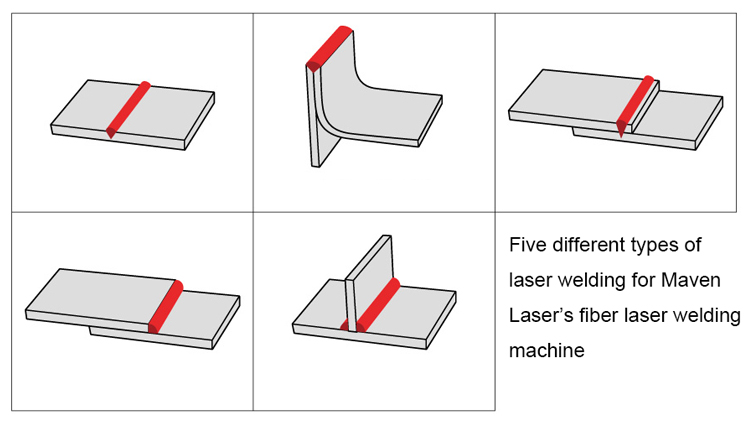

Generally consists of welding host and welding table, the laser beam coupled to the fiber, after long-distance transmission, processed into parallel light focus on the workpiece to implement continuous welding, due to the continuity of light so the welding effect is solid, fine and beautiful weld seam. According to different industries and different needs, the machine can be matched with the shape and table according to the production site to achieve automatic operation, fully meet the needs of different customers Can butt weld, stack weld, seal weld to the workpiece, fast speed, can meet the 01mm-5mm thickness of material welding High power gas protection, can work for a long time Laser beam energy adjustable, adjustable movement speed, can be a variety of welding processing Laser welding is highly automated and can be controlled by computer, with high welding speed and easy access to any complex shapes

Generally consists of welding host and welding table, the laser beam coupled to the fiber, after long-distance transmission, processed into parallel light focus on the workpiece to implement continuous welding, due to the continuity of light so the welding effect is solid, fine and beautiful weld seam. According to different industries and different needs, the machine can be matched with the shape and table according to the production site to achieve automatic operation, fully meet the needs of different customers Can butt weld, stack weld, seal weld to the workpiece, fast speed, can meet the 01mm-5mm thickness of material welding High power gas protection, can work for a long time Laser beam energy adjustable, adjustable movement speed, can be a variety of welding processing Laser welding is highly automated and can be controlled by computer, with high welding speed and easy access to any complex shapes

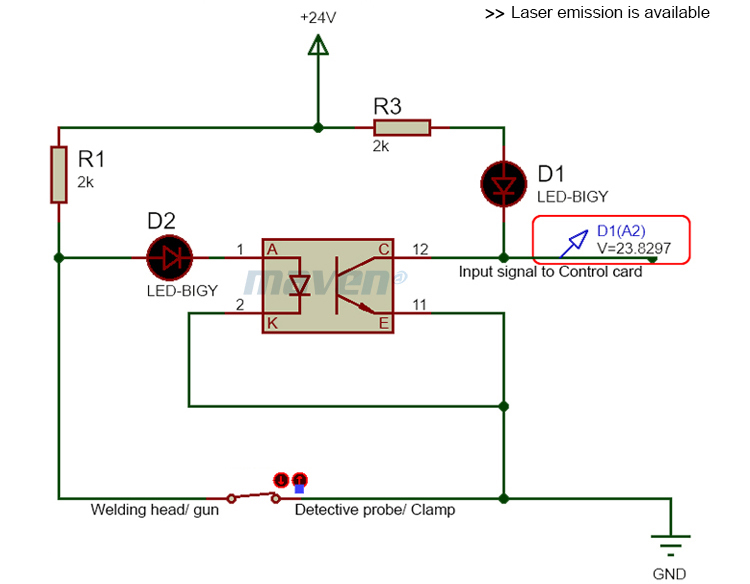

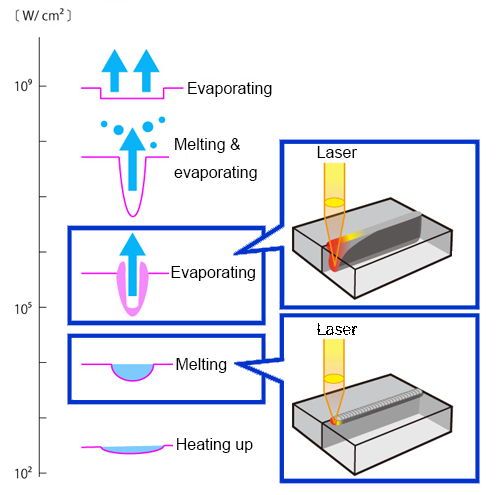

Different density of laser beam result in different laser welding types. Material: Aluminum/ stainless steel/ carbon Reflection and its own prosperity result in different laser welding parameters. Gap width: Normally gap width should be less than 0.5mm. Wire feeder needed when the value ranges from 0.5mm to 1.0mm. Melt depth: Usually less than 3.0mm, double-sided laser welding is suggested when it comes to thicker material. Qualification of workers: User friendly, and easy to operate.Laser emission's availability Status 1. Welding head is connected with detective probe, whether directly or not. 2. VDC input signal is DC24V. Result Laser shoot is available now Remark: Automatic laser welding system have similar laser usage safety protect rules

Different density of laser beam result in different laser welding types. Material: Aluminum/ stainless steel/ carbon Reflection and its own prosperity result in different laser welding parameters. Gap width: Normally gap width should be less than 0.5mm. Wire feeder needed when the value ranges from 0.5mm to 1.0mm. Melt depth: Usually less than 3.0mm, double-sided laser welding is suggested when it comes to thicker material. Qualification of workers: User friendly, and easy to operate.Laser emission's availability Status 1. Welding head is connected with detective probe, whether directly or not. 2. VDC input signal is DC24V. Result Laser shoot is available now Remark: Automatic laser welding system have similar laser usage safety protect rules

Features and laser welding types Welding with high demand. Energy density is high and the heat effect is partially small, strain due to heat can be kept low. Easy transmission of fiber laser source, which can increase productivity Non-contact, highly flexible welding is possible

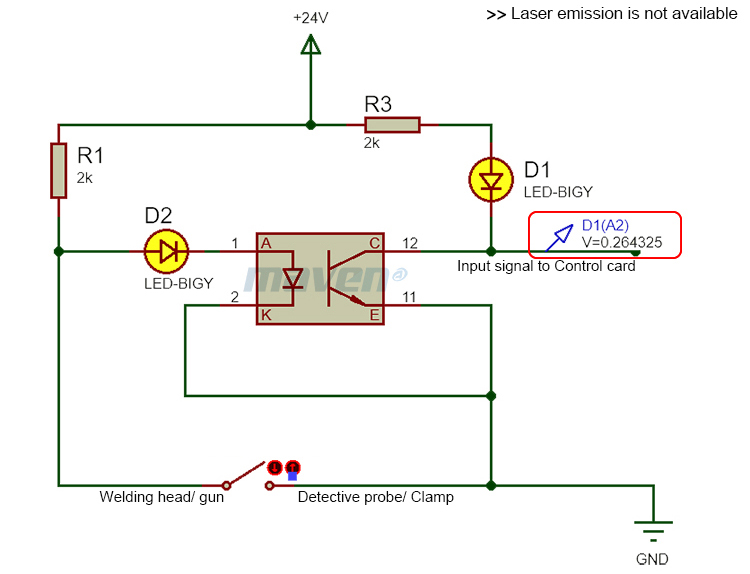

Features and laser welding types Welding with high demand. Energy density is high and the heat effect is partially small, strain due to heat can be kept low. Easy transmission of fiber laser source, which can increase productivity Non-contact, highly flexible welding is possible Laser emission not available 1. Welding head is not connected with detective probe, whether directly or not. 2. VDC input signal is DC0V. Laser shoot is not available Automatic laser welding system have similar laser usage safety protect rules

Laser emission not available 1. Welding head is not connected with detective probe, whether directly or not. 2. VDC input signal is DC0V. Laser shoot is not available Automatic laser welding system have similar laser usage safety protect rules| Usage | Industry Welding |

| Dimensions | 1200*1130*1650 mm |

| Laser Source Brand | Max, JPT, Raycus |

| Servo Motor Brand | Panasonic |

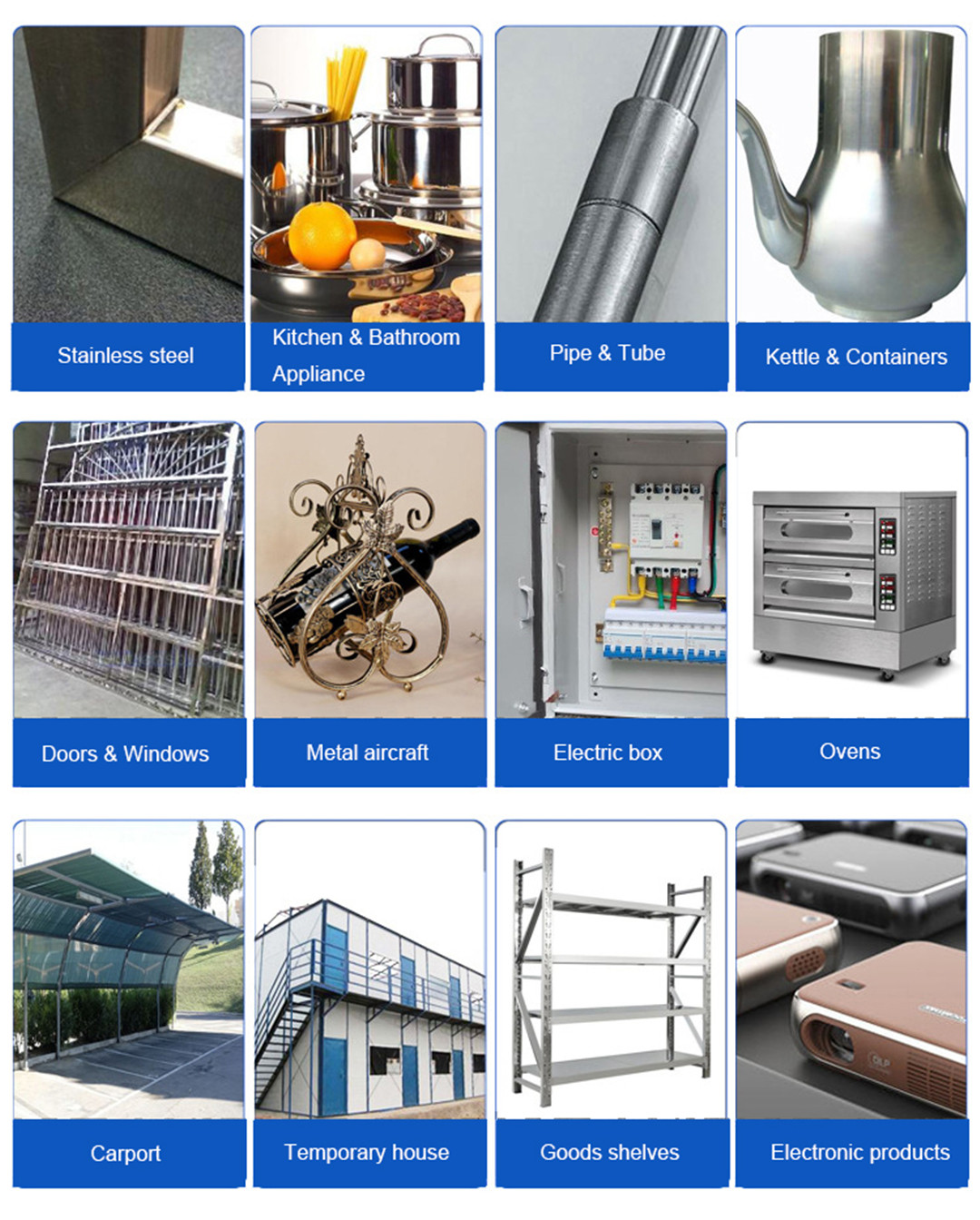

| Applicable industries | Hotels, Garment Shop, Building Material Shops |

| Welding mode | CW/Pulse |

| Welding gap requirement | < 1mm |

| Input power | AC 380V |

| 4-Axis | X Y Z R(welding head) R(Pneunamic clamp) |

| Max. Output power | 4000W |

| Wavelength | 1064 nm |

| Control system brand | Syntec or self-developed |

| Warranty | 1.5 years |

| Power adjustment range | 10%-100% |

| Weld thickness | 0.2-6 mm |

| Chilling | Water chilling |

| Power of machine | ≤5000W |

| Fiber length | 10 m or specified |

| Material | Protective gas | Thickness(mm) | 500W | 1000W | 1500W |

| Aluminum | N2/Ar | 1 | √ | √ | |

| 1.2 | √ | √ | |||

| 1.5 | √ | √ | |||

| 2 | √ | √ | |||

| 2.5 | √ | ||||

| Stainless Steel | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | √ | ||

| 2 | √ | √ | |||

| 2.5 | √ | √ | |||

| 3 | √ | ||||

| Carbon Steel | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | √ | ||

| 2 | √ | √ | |||

| 2.5 | √ | √ | |||

| 3 | √ | ||||

| Galvanized Sheet | N2/Ar | 0.5 | √ | √ | √ |

| 0.8 | √ | √ | √ | ||

| 1 | √ | √ | √ | ||

| 1.2 | √ | √ | √ | ||

| 1.5 | √ | √ | |||

| 2 | √ | √ | |||

| 2.5 | √ |

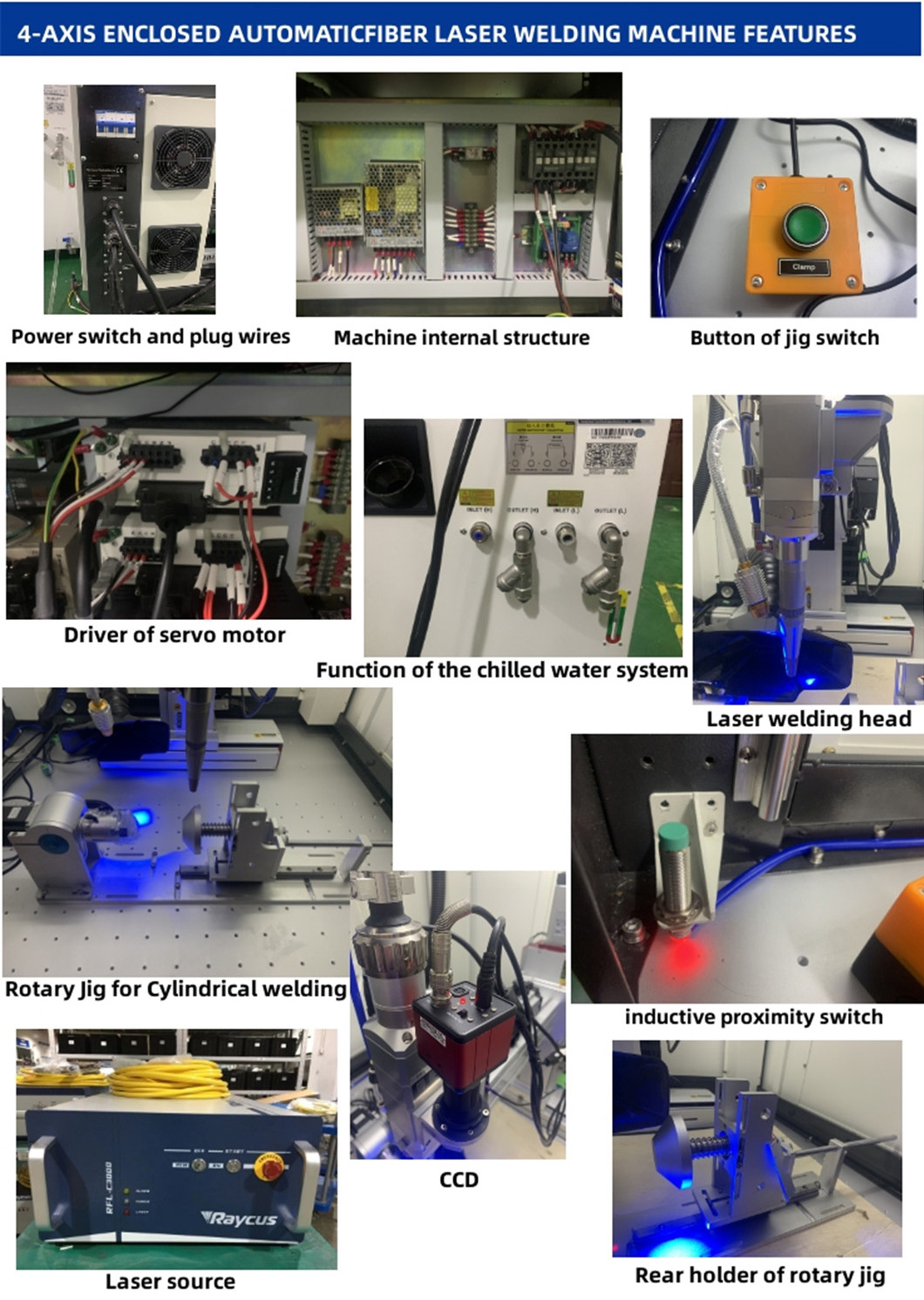

Machine components show, our 4-AXIS Enclosed Automatic Fiber Laser Welding Machine include Power switch and plug wires, button of jig switch, diver of servo motor, function of chilled water system, Rotary Jig for Cylindrical welding, Laser source, CCD Screen, Rear holder of rotary jig, inductive proximity switch and laser welding head

Machine components show, our 4-AXIS Enclosed Automatic Fiber Laser Welding Machine include Power switch and plug wires, button of jig switch, diver of servo motor, function of chilled water system, Rotary Jig for Cylindrical welding, Laser source, CCD Screen, Rear holder of rotary jig, inductive proximity switch and laser welding head

- High resolution visual CCD monitor

- English version software and labels

- Door safety function laser protective window