Laser cutting is a revolutionary technology that has transformed the way materials are cut and processed. Industrial manufacturing has been enhanced by the use of laser cutting technology, but it is also becoming increasingly popular with schools, small businesses, and hobbyists. This is because laser cutting has a number of benefits that traditional cutting methods do not have, including speed, precision, and flexibility.

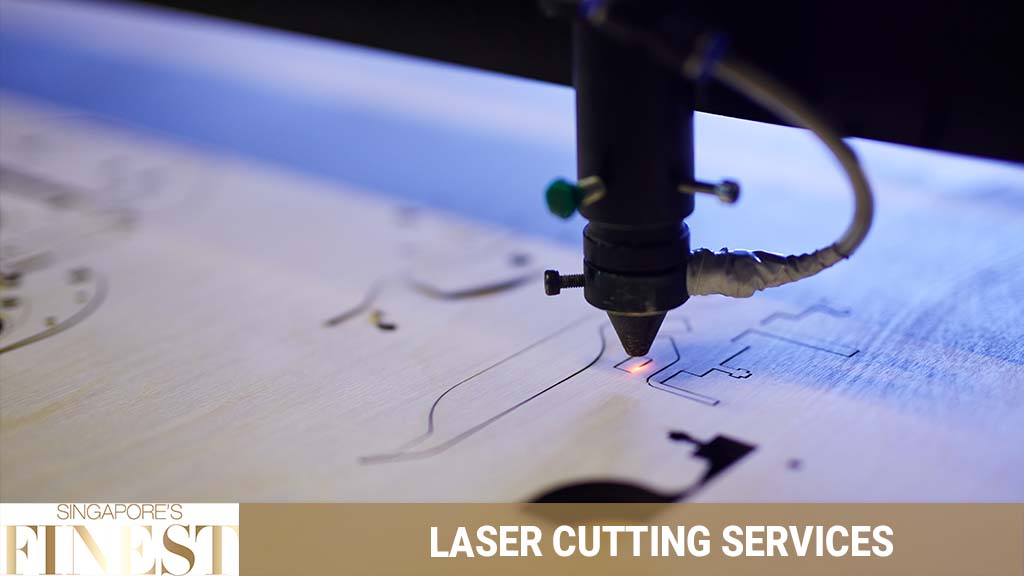

Laser cutting works by using a high-power laser that is directed through optics onto the material. CNC or G-code is used to direct the material or the laser beam generated by the laser optics. A motion control system is used to follow the pattern that needs to be cut onto the material. The focused laser beam is then directed at the material, which can melt, burn, vaporize away, or be blown away by a jet of gas, leaving behind an edge with a high-quality surface finish.

One of the biggest advantages of laser cutting technology is its speed. Laser cutting is much faster than traditional cutting methods, which means that more work can be done in less time. Additionally, the precision of laser cutting is unparalleled. Laser cutting can cut materials with extreme accuracy, leading to a high-quality surface finish. The flexibility of laser cutting technology is also a notable benefit. Laser cutting can be used to cut a wide range of materials, from flat-sheet material to structural and piping materials.

Industrial laser cutters are widely used in manufacturing processes because of their efficiency and accuracy. They are capable of cutting materials faster and with greater precision than other cutting methods. Additionally, they can be programmed to cut a wide range of patterns, including intricate designs that would be difficult or impossible to cut using traditional techniques.

Laser cutting is also becoming increasingly popular with schools, small businesses, and hobbyists. This is because laser cutters are now more affordable and accessible than ever before. Schools are using laser cutters to teach students about technology and manufacturing. Small businesses and hobbyists are using laser cutters to create a wide range of products, from custom jewelry to ornate home decor items.

In conclusion, laser cutting is a technology that has transformed the manufacturing industry and is now becoming increasingly popular with schools, small businesses, and hobbyists. The speed, precision, and flexibility of laser cutting technology make it an excellent choice for a wide range of applications. Industrial laser cutters are widely used in manufacturing processes to cut a wide range of materials faster and with greater precision than other cutting methods. As laser cutters become more affordable and accessible, they are also being used in schools, small businesses, and by hobbyists to create a variety of products with high-quality surface finishes.